-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

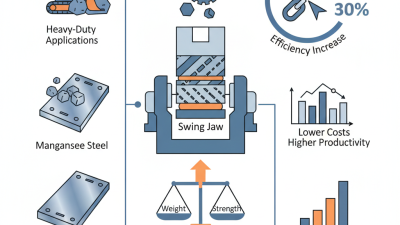

The Bowl Liner Cone Crusher stands out as a key component in modern mining operations. Its innovative design enhances efficiency and overall productivity. The 2026 model promises advancements that can redefine crushing processes.

With a focus on durability, the Bowl Liner Cone Crusher offers materials that withstand extreme conditions. This feature reduces wear and tear, which can lead to costly downtime. Operators can expect more reliability and less maintenance. Attention to detail in design ensures that even minor flaws are addressed, leading to fewer issues in practice.

However, challenges remain. Operators must be aware of adapting to new technologies. Embracing change can be difficult but necessary for success. Continuous evaluation of these crushers will help identify areas for improvement. The potential benefits of the 2026 Bowl Liner Cone Crusher are substantial, provided users are ready to embrace the evolution.

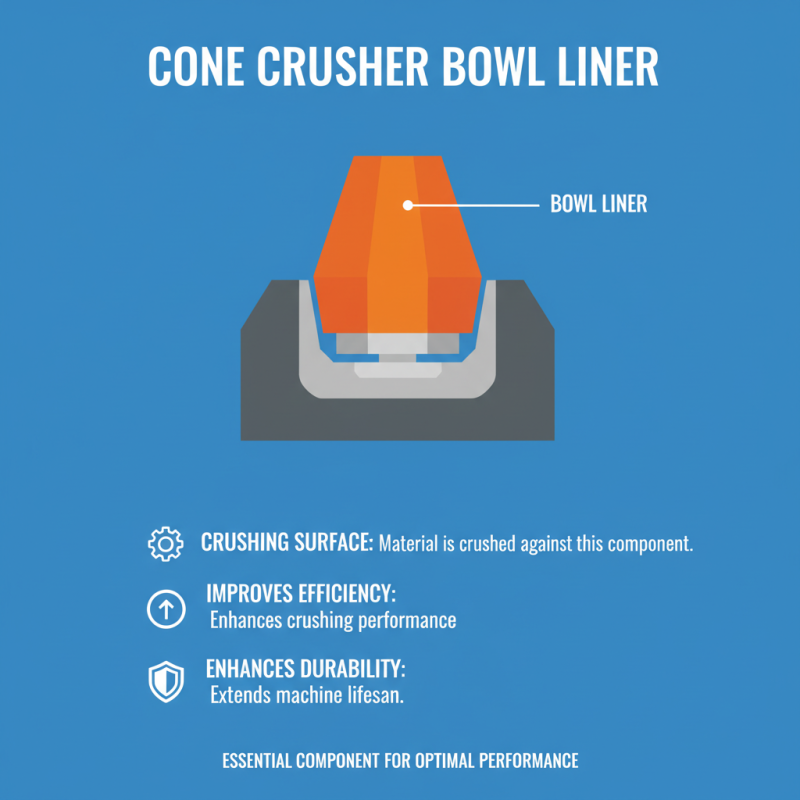

The bowl liner plays a crucial role in cone crushers. It is an essential component that directly impacts the machine's performance. The bowl liner is positioned in the top section of the crusher. It provides a surface against which the material is crushed. A properly fitted bowl liner can improve crushing efficiency and enhance durability.

When choosing a bowl liner, consider the material type. High-quality materials can resist wear and reduce replacement frequency. Look for options with good shock absorption. This can extend the life of both the liner and other components. Over time, wear and tear can reduce efficiency. Regular inspection is necessary.

**Tip:** Always monitor the liner's condition. Signs of wear can lead to decreased performance. Consider using visual markers to identify potential issues. This proactive approach can save time and money.

Bowl liners can come in various profiles. Different profiles determine how materials are processed. Experimenting with these profiles may yield even better results. Be cautious with adjustments; sometimes, the best configuration takes time to find. You may need to revisit your choices repeatedly.

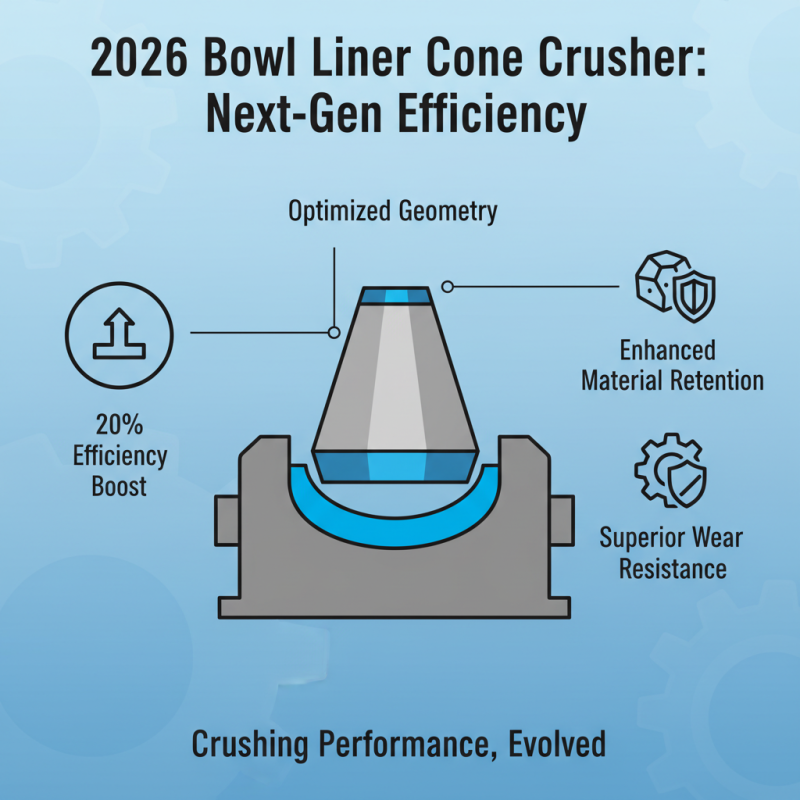

The 2026 bowl liner design introduces several key features that enhance performance. The shape and material are optimized for better wear resistance. This ensures longer life and reduced downtime. It’s crucial for mining and aggregate industries, where reliability is essential.

One notable characteristic is the improved surface texture. This texture helps stabilize the crushing process. It increases friction, leading to better compression of materials. However, this feature may require adjustments in equipment settings. Operators might need extra training to maximize effectiveness.

Another point to consider is the weight of the liner. While a heavier design can aid in crushing efficiency, it also poses handling challenges. Lifting and installation can become more cumbersome. Regular maintenance routines must adapt to these changes to maintain operational standards. This also leads to reflections on the balance between durability and practicality.

| Feature | Description | Benefits |

|---|---|---|

| Material Composition | High manganese steel for enhanced durability and wear resistance. | Longer liner life resulting in reduced downtime and lower replacement costs. |

| Design Geometry | Optimized shape for efficient crushing and better material flow. | Increased throughput and improved particle size distribution. |

| Heat Treatment | Special heat treatment process to enhance hardness and toughness. | Better performance under high-stress conditions for consistent output. |

| Compatibility | Designed to fit various cone crusher models seamlessly. | Ease of integration with existing equipment minimizing installation time. |

| Warranty | Extended warranty coverage for peace of mind. | Protection against premature failure, enhancing investment security. |

The 2026 bowl liner cone crusher presents unique advantages for crushing operations. It enhances productivity with its high wear resistance. The durable material allows for prolonged use under tough conditions. This ultimately leads to lower operational costs over time.

Another significant feature is its precise fit in the crushing chamber. Proper alignment reduces wear on both the liner and the underlying components. This not only increases efficiency but also minimizes the need for frequent replacements. Operators may find that achieving this efficiency requires careful calibration. Overlooking small adjustments might lead to suboptimal performance.

Incorporating the 2026 bowl liner can lead to smoother operations. However, it is crucial to monitor abrasion levels regularly. While the liner is designed to withstand harsh conditions, neglecting maintenance can result in unexpected downtime. This highlights the need for a proactive approach to manage wear and tear effectively. Regular assessments can help maintain peak performance over time.

Maintaining bowl liners in cone crushers is crucial for their longevity and optimal function. Regular inspections should be part of your routine. Look for signs of wear and tear. Even minor damage can lead to bigger problems down the line. Replace worn liners promptly to avoid unnecessary complications.

Cleaning is another essential aspect. Dust and debris can build up, affecting performance. Use a compressed air system to blow out any accumulated materials. This simple action can greatly enhance the efficiency of the crusher. Regular lubrication is vital too. Keep moving parts well-greased to minimize friction.

Monitoring operating conditions is key. Listen for unusual sounds while the machine runs. They may signal issues with the bowl liners. Be proactive about adjustments. If there’s vibration or excessive heat, it’s time to pause and assess. Perfect maintenance may not always be achievable, but consistent effort can lead to better performance.

The 2026 bowl liner cone crusher has introduced significant improvements over earlier models. Compared to previous iterations, the new design enhances material retention and wear resistance. Industry reports indicate that these advancements can lead to a 20% increase in operational efficiency. The geometry of the bowl liner has been optimized for better crushing performance.

Historical data show that earlier bowl liners often suffered from quick degradation, causing costly downtime. The 2026 model addresses these issues with upgraded materials that extend service life. However, some users have noted that the new design may require modifications to existing machinery. This transition period can create challenges for operators accustomed to older models. Feedback suggests that while the performance is a notable improvement, the learning curve may affect initial productivity.

Another aspect to consider is the impact of these changes on maintenance routines. With increased efficiency, maintenance schedules may need to be adjusted. Reports highlight that some operators found it hard to keep up with the new demands. Adapting to these innovations presents potential pitfalls but can also yield substantial rewards if managed correctly. These insights highlight the importance of thorough analysis before transitioning to the latest bowl liner technology.