-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

When selecting the right Cone Crusher Bowl Liner, it is essential to consider various factors that contribute to optimal crushing performance. The bowl liner plays a pivotal role in the efficiency of the cone crusher, as it directly impacts the quality of the output material and the overall productivity of the crushing process. An ideal bowl liner not only enhances the lifespan of the equipment but also ensures that the crushed materials meet the desired specifications.

The process of choosing the correct Cone Crusher Bowl Liner involves understanding the specific requirements of your operation, including the type of material being processed and the intended application. Different applications demand different liner profiles and materials, which can significantly affect the crusher's performance. By analyzing these factors, operators can make informed decisions that improve both performance and profitability.

In addition, it is crucial to monitor factors such as wear patterns and maintenance schedules, as these can influence the effectiveness of the bowl liner over time. Selecting a high-quality cone crusher bowl liner that aligns with your operational needs will ultimately lead to better results and a more efficient crushing process.

Cone crusher bowl liners are crucial components that directly affect the performance and efficiency of the crushing process. These liners play a vital role in the interaction with the mantle during the crushing cycle, where they create the necessary space for material reduction. Understanding their shape, material, and wear patterns is key to optimizing crusher performance. Selecting the right bowl liner that aligns with the material characteristics and the desired final product size can significantly enhance throughput and extend equipment lifespan.

Tips: When choosing a bowl liner, consider the material being crushed. Harder materials may require a different liner profile compared to softer ones to ensure maximum wear resistance and performance. Regular inspection of the bowl liner for wear can also help in scheduling timely replacements, minimizing downtime and maintaining consistent performance levels.

Another important factor to consider is the design of the bowl liner. Different configurations can impact the flow of material and the efficiency of the crushing process. Ensuring a proper fit and alignment within the crusher can lead to better material handling and a reduction in operational issues. It's advisable to consult with experts or reference industry guidelines to make the most informed choice in bowl liner selection.

When selecting a cone crusher bowl liner, it is crucial to understand the various types available, as each is designed for specific applications and wear patterns. Bowl liners typically come in different profiles, such as standard and short head configurations, catering to various stone sizes and crushing requirements. The standard bowl liner is well-suited for producing medium-sized products, while the short head liner is ideal for finer crushing, enabling manufacturers to tailor their equipment to meet desired output specifications.

Additionally, the material composition of the bowl liner significantly impacts its performance and durability. Common materials include high manganese steel, which offers excellent wear resistance and the ability to withstand high-impact forces during crushing operations. Some liners may also be available in alloys that further enhance hardness and extend operational life. Understanding these factors will allow operators to choose the right bowl liner that not only fits their particular crusher model but also optimizes performance and longevity in overcoming challenging material properties.

Selecting the right cone crusher bowl liner is crucial for achieving optimal performance in crushing operations. When choosing a bowl liner, several key factors must be considered to enhance efficiency and prolong the lifespan of the equipment. Firstly, the material composition of the bowl liner plays a significant role in its wear resistance and durability. According to recent industry reports, high manganese steel and alloyed materials can provide superior toughness and impact resistance, significantly improving the liner's service life. Statistical analyses indicate that liners made from these advanced materials can yield a performance increase of approximately 20% compared to standard options.

Another important consideration is the profile of the bowl liner. The design of the liner must be compatible with the specifics of the feed material and the desired output size. Research shows that optimizing the liner profile can lead to improved crushing efficiency and reduced energy consumption. Studies have demonstrated that a well-matched bowl liner can achieve reduction ratios up to 6:1, thereby maximizing throughput. Moreover, understanding the operational parameters, such as the crushing chamber's design and the material's properties, is essential for selecting a bowl liner that not only meets but exceeds operational demands.

Selecting the right cone crusher bowl liner is essential for maximizing both durability and efficiency in mineral processing operations. The material composition directly impacts the lifespan and performance of the liner. According to a recent industry report from the Mining and Metallurgy Society, the most commonly used materials include manganese steel, alloy steel, and high-carbon chrome steel, each offering unique benefits tailored for specific crushing applications. Manganese steel, for instance, is renowned for its wear resistance due to its ability to work-harden during operation, making it an excellent choice for high-impact crushing scenarios.

In addition to conventional materials, emerging developments in composite materials are showing promise in enhancing bowl liner performance. Research published in the Journal of Materials Engineering indicates that liners made of a combination of high-strength steel and ceramic compounds exhibit superior wear properties, extending operational life by up to 30% compared to traditional steel liners. Furthermore, analyzing the specific material composition can lead to tailored solutions that not only improve endurance but also increase crushing efficiency by optimizing the shape and rigidity of the liner. This holistic approach ensures that businesses can further reduce operational costs while maintaining the quality of the end product.

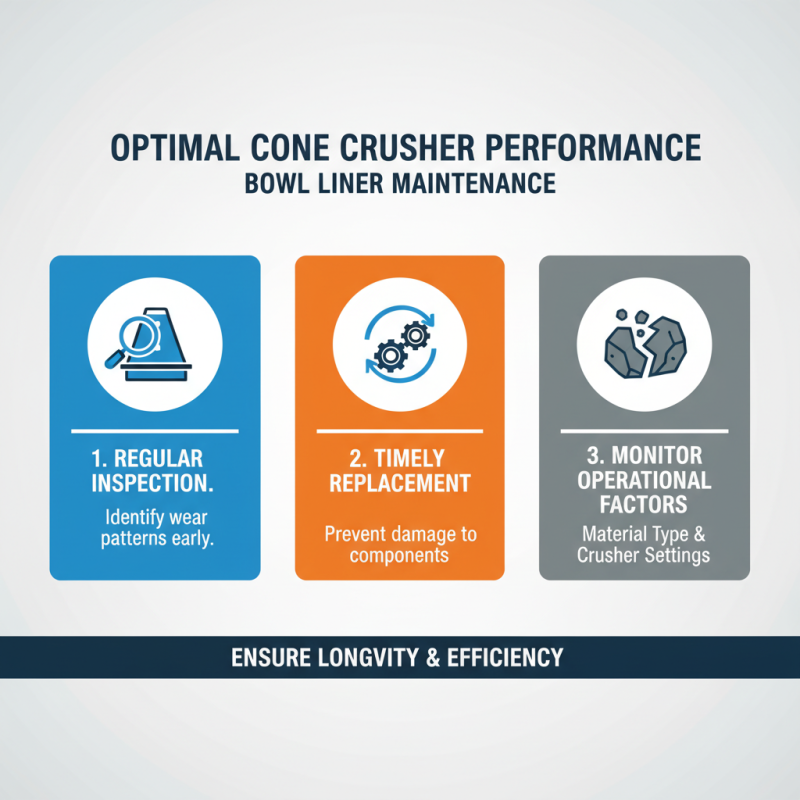

Maintaining and replacing cone crusher bowl liners is essential for ensuring optimal performance and longevity of your equipment. Regular inspection of the bowl liners can help identify wear patterns early, allowing for timely replacements before significant damage occurs to the crusher components. It is crucial to monitor the wear profiles and consider the operational conditions that might accelerate wear, such as the type of material being crushed and the crusher's operating parameters.

When it comes to replacing bowl liners, following a systematic approach is vital. First, ensure that all necessary safety protocols are observed before disassembling the cone crusher. Carefully remove the old bowl liner and clean the mounting surfaces to prevent debris from interfering with the new liner's fit. Selecting the right bowl liner design can enhance the crusher's efficiency, so take the time to consider factors like material composition, shape, and size based on your specific crushing requirements. After installing the new liner, perform a test run to verify that everything functions correctly and make any necessary adjustments to the operating settings for optimal performance. Regular maintenance checks will further extend the life of the bowl liners and maintain your cone crusher's efficiency.