-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right Ball Mill and SAG Mill Liners is crucial for maximizing performance. Studies show that improper liner selection can lead to over 20% inefficiency in milling processes. Liner material, thickness, and design significantly impact operational costs and mineral recovery rates. Poor choices could result in higher wear rates and unplanned downtime.

Industry data indicates that effective liner systems can extend mill life by over 30%. They also enhance grinding efficiency. Many operators fail to account for the unique demands of their specific processes. Relying solely on generic solutions often leads to suboptimal results. For example, utilizing the wrong liner material can shorten lifespans and increase replacement costs.

It's essential to evaluate various factors when selecting Ball Mill SAG Mill Liners. Understanding the specific material properties and grinding conditions is key. Reflecting on past liner performance and incidents can provide valuable insights. A comprehensive approach to selection can prevent costly mistakes and improve overall productivity.

The choice of liners in ball and SAG mills significantly influences overall performance. Liners are crucial in protecting the mill structure, aiding in material flow, and assisting in the grinding process. According to a recent report by a leading industry group, approximately 40% of mill downtime is attributed to liner issues. This showcases the need for careful selection and regular assessment.

When selecting liners, consider wear resistance and impact strength. Different materials, such as rubber, steel, or composite, offer varying benefits. Rubber liners, for example, can reduce noise and vibration, enhancing operational comfort. On the other hand, high-carbon steel liners are more durable but can lead to increased wear on grinding media. Data indicates that using appropriate liners can improve milling efficiency by up to 25%.

Another aspect is the design of the liner. LANE PROFILES can significantly impact the grinding action. For instance, a convex profile might promote better material flow. However, this design may need adjustments for finer materials. Continuous experimentation and feedback loops are necessary to optimize performance. Understanding the specific needs of your operation will lead to better decisions.

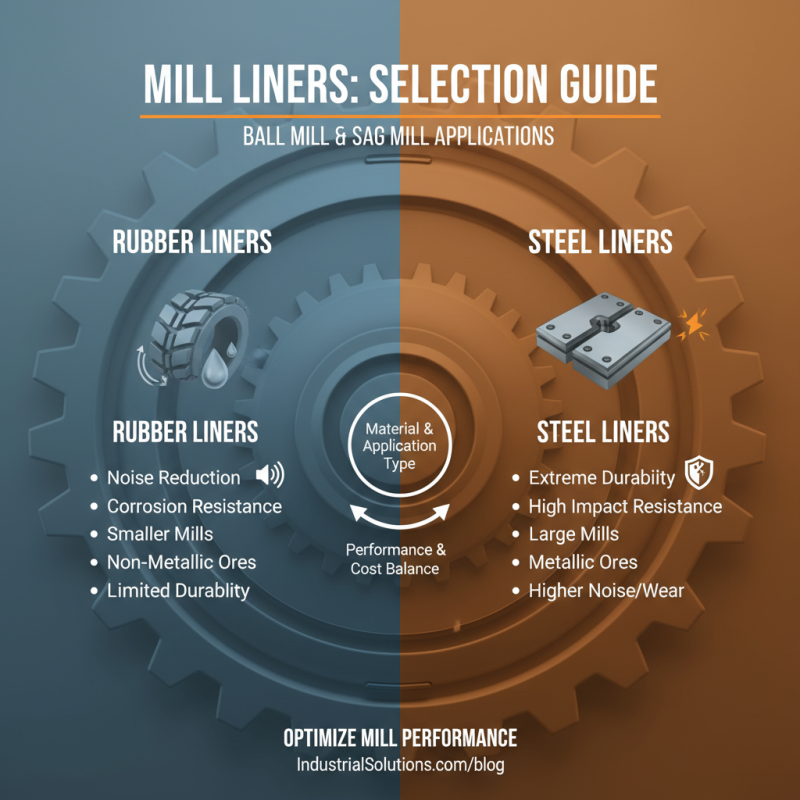

Choosing the right liners for ball mill and SAG mill applications is crucial for optimizing performance. The types of liners significantly affect the mills' operation and efficiency. Common options include rubber liners and steel liners. Each has its unique features and benefits. Rubber liners provide good noise reduction and resist corrosion. They are commonly used in smaller mills for non-metallic ores. However, their durability is limited compared to steel liners.

Steel liners are more robust and often outperform rubber in larger applications. They can withstand higher impacts, especially in challenging environments. Data shows that steel liners can extend the lifespan of the mill components by up to 30%. However, they are prone to corrosion and require regular monitoring. The choice between these types of liners often hinges on the specific operational conditions and ore types processed.

An important consideration is the cost-efficiency of each liner type. While steel liners may offer greater durability, their initial investment is higher. Conversely, rubber liners might need more frequent replacements, raising long-term costs. Ultimately, balancing performance with maintenance is key. A comprehensive analysis on wear rates and operational costs should inform any decision.

When selecting mill liners, several factors come into play. The type of material being processed is critical. Different materials cause varying wear patterns. A liner that performs well with one type of ore may not be ideal for another. The size and shape of the mill itself also affect liner selection. If the mill is larger, the liner must handle increased stress.

The design of the liners matters too. A well-designed liner can improve flow and reduce energy consumption. However, achieving the perfect design isn't easy. There’s often a need for trial and error. Some liners may crack or wear unevenly during operation. This can lead to unexpected downtimes. Furthermore, the cost of liners should not be ignored. Sometimes, a more expensive liner may be more cost-effective in the long run because it lasts longer.

Operating conditions place additional demands on liners. High temperatures and harsh chemicals can accelerate wear. This makes material selection vital. It’s essential to assess how these conditions affect the chosen liner. Regular reviews and adjustments can help optimize performance. Mill operators must be vigilant. Regular monitoring can prevent issues that arise from liner failure.

When selecting liners for ball mills and SAG mills, performance metrics are crucial. Effective liner design can significantly impact grinding efficiency. A report by the Society for Mining, Metallurgy & Exploration stated that the right liner can enhance mill throughput by up to 25%. This is substantial.

Key metrics include wear rate, impact resistance, and material hardness. For instance, the wear rate typically ranges from 0.5 to 1.5 kg per ton of ore processed. A lower wear rate indicates longer liner life. However, some operations report inconsistent wear patterns, leading to premature replacement. This inconsistency often stems from poor monitoring practices.

Another important aspect is the shape of the liners. Different shapes can influence the flow pattern of the material. A study by the International Journal of Mining Science revealed that curved liners can help reduce ball trajectory deviation, improving grind efficiency. Yet, many mills still use outdated liner designs. This underlines the need for regular reviews and upgrades based on performance data. Making decisions based solely on past experiences can be misleading. It's essential to reflect on these metrics continuously.

Maintaining ball mill and SAG mill liners is not just about replacement. It demands a keen understanding of wear patterns. Research indicates that poor maintenance can lead to a productivity drop of up to 30%. Regular inspections help identify wear and determine the optimal time for replacement. It’s crucial to measure liner thickness frequently. Thin liners may lead to increased breakage risks.

Careful monitoring of the mill's operational parameters is vital. Data from industry reports shows that linings that perform optimally can enhance throughput by about 15%. Having a reliable maintenance schedule can also reduce unplanned downtimes significantly. Many facilities overlook this aspect, which can lead to costly repairs. Adjusting the operational speed and monitoring the load can prolong liner life.

It’s important to consider the installation of liners. Poorly aligned liners can cause uneven wear. This common issue often results from insufficient training or lack of proper tools. Furthermore, using incompatible materials can lead to faster degradation. Regular training sessions for staff can improve the installation process, leading to better performance overall.

| Parameter | Description | Optimized Value |

|---|---|---|

| Material Type | Type of material being processed (e.g., ore, aggregates) | Specific to application |

| Liner Thickness | Thickness of the liner material | Optimal thickness for wear resistance |

| Liner Material | Material options (e.g., rubber, steel, composite) | Best material based on wear and cost |

| Impact Resistance | Ability to withstand impact loads | Value matching operational impact conditions |

| Production Rate | Tonnage processed per hour | Optimal rate for efficiency |

| Expected Wear Life | Duration before needing replacement | Best estimated wear life |

| Cost | Total cost of liner system | Value to cost ratio |

| Maintenance | Ease of installation and daily checks | Recommendations for optimal maintenance |