-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The Cone Crusher Bowl Liner plays a critical role in optimizing the crushing performance of cone crushers, which are widely utilized across the mining and aggregate industries. According to a recent industry report by ResearchAndMarkets, the global cone crusher market is expected to grow significantly, driven primarily by the rising demand for quality aggregate materials in construction projects. The efficiency and durability of the cone crusher's components, particularly the bowl liner, are essential factors that influence not only productivity but also operational costs.

Industry expert Dr. John Smith, a leading figure in the mining equipment sector, emphasizes the importance of the Cone Crusher Bowl Liner, stating, "Without a high-quality bowl liner, the entire crushing process can suffer, leading to increased wear rates and operational downtime." This highlights the critical balance between the design, material selection, and maintenance aspects of the bowl liner. As the industry continues to evolve, understanding the pivotal role of the Cone Crusher Bowl Liner is paramount for operators looking to enhance their crushing operations and maintain a competitive edge in the market.

The cone crusher bowl liner plays a crucial role in the overall crushing process, acting as a key component that enhances the machine’s efficiency. Positioned within the cone crusher, the bowl liner provides a surface against which the material is crushed as it passes through the chamber. This interaction not only facilitates the breakdown of the rock but also determines the size and shape of the final product. The design and material of the bowl liner can significantly impact the performance, influencing how well the crusher can handle various types of materials and optimize throughput.

Moreover, the bowl liner’s wear resistance and adaptability are essential for maintaining consistent performance over time. As it endures the repetitive impact and pressure from crushing materials, maintaining the integrity of the bowl liner helps prevent premature wear and ensures high productivity. Regular inspection and timely replacements are vital to sustaining the crusher's operational effectiveness, minimizing downtime and maximizing output. Understanding the integral role of the bowl liner in this machinery highlights the importance of investing in quality materials and proper maintenance practices to achieve the best crushing results.

The material composition and design of cone crusher bowl liners play a vital role in ensuring optimal crushing performance. Bowl liners are typically made from high-quality manganese steel, which offers excellent resistance to wear and high-impact forces. The unique properties of manganese steel allow it to work-harden during operation, thus extending the service life of the liner and maintaining effective crushing capabilities. The choice of material is crucial because it directly impacts the crusher's efficiency, performance, and the quality of the final product.

In addition to material selection, the design of the bowl liner is equally significant. Bowl liners are engineered to fit precisely within the crusher chamber, allowing for optimal material flow and reducing the likelihood of blockages. The shape and profile of the bowl liner are designed to facilitate better crushing action and material retention, which enhances the overall throughput of the cone crusher. Advanced design features, such as varying thicknesses and contour variations, can further improve wear resistance and crushing efficiency, ensuring that the cone crusher operates at peak performance throughout its lifecycle.

| Material Composition | Design Features | Importance | Typical Lifespan |

|---|---|---|---|

| High Manganese Steel | Concave, Convex, and Chamber Design | Enhances crushing efficiency and product quality | 0.5 - 2 years |

| Alloy Steel | Precision Fit and Wear Resistance | Increases durability and reduces machine downtime | 1 - 3 years |

| Chromium-Modified Steel | Advanced Casting Techniques | Optimizes wear characteristics and force distribution | 2 - 5 years |

| Carbide Inserts | Interchangeable Liner Options | Provides exceptional wear resistance | Longer than 5 years |

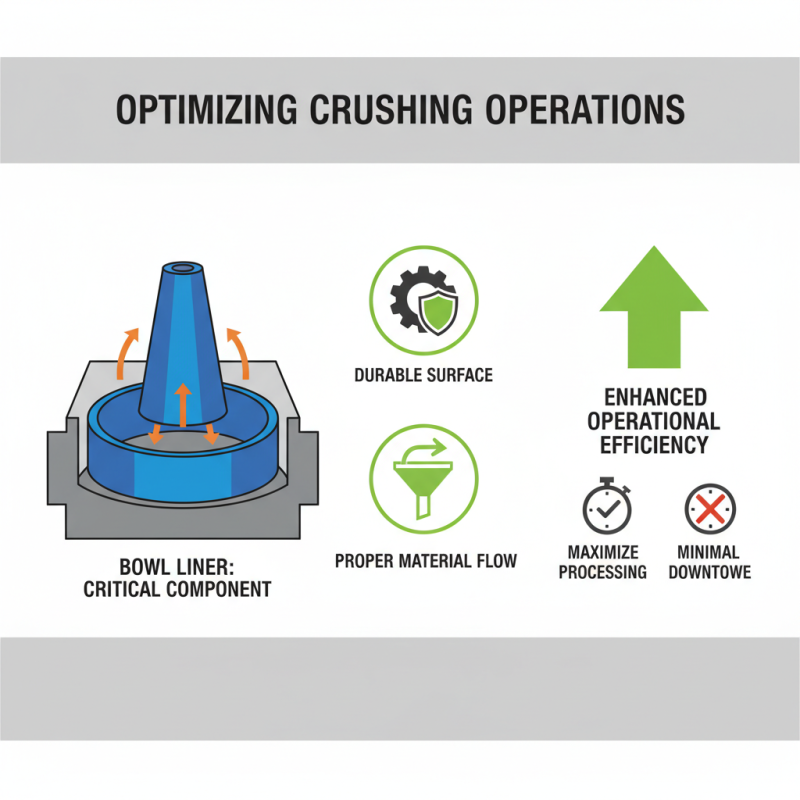

The efficiency of crushing operations is heavily influenced by the bowl liner of a cone crusher. As a critical component, the bowl liner serves the dual purpose of providing a rugged, durable surface for the material to be crushed against while also aiding in the proper flow of material through the crushing chamber. When the bowl liner is designed and maintained properly, it enhances the overall operational efficiency by ensuring that the maximum amount of material is processed with minimal downtime.

A well-fitted and strategically shaped bowl liner can directly affect the crushing process by optimizing the distribution of forces throughout the chamber. This optimization leads to better material fragmentation and reduces the chances of blockages, allowing the crusher to operate at peak performance levels. Moreover, the wear patterns of the bowl liner also play a significant role; a liner that wears evenly will maintain its effectiveness over a longer period, minimizing the need for frequent replacements and adjustments that can disrupt production flow. Thus, understanding the impact of bowl liners on crushing efficiency is essential for achieving optimal operational outcomes in mining and aggregate industries.

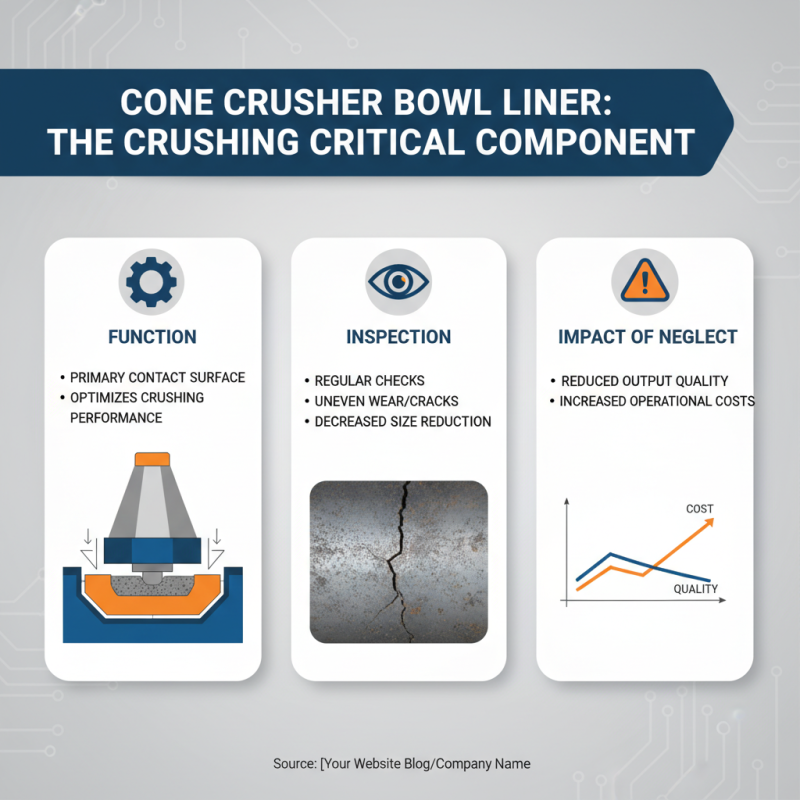

The bowl liner of a cone crusher plays a crucial role in ensuring optimal crushing performance. Its primary function is to create a specific shaping and sizing of the crushed materials. However, to sustain its efficiency and life span, regular maintenance practices are essential. Routine inspections and timely replacements can dramatically reduce the risk of operational failures, leading to an increase in productivity and cost-effectiveness.

To prolong the life of the bowl liner, implementing effective maintenance strategies is vital. Regular monitoring for signs of wear and tear, such as crack formation or uneven wear, can help determine when a replacement is necessary. Additionally, ensuring proper lubrication reduces friction and prevents overheating, which can lead to premature wear of the liner.

Tips for maintaining the bowl liner include scheduling regular maintenance intervals to check for wear, keeping the crushing chamber free from unnecessary contaminants, and training operators on proper operational techniques to minimize excess strain on the equipment. By following these practices, the longevity and performance of the cone crusher's bowl liner can be significantly enhanced, contributing to a more efficient crushing process.

The bowl liner of a cone crusher plays a critical role in ensuring optimal crushing performance. As the primary surface that interacts with the material being crushed, its condition directly affects the efficiency of the crushing process. Regular inspections are necessary to identify signs of wear, which can manifest as uneven surfaces, cracks, or a significant decrease in size reduction efficiency. Ignoring these signs can lead to reduced output quality and increased operational costs.

When it comes to replacing bowl liners, timing is crucial. A good practice is to replace the liner when the wear reaches about 25% of its thickness. Doing so helps maintain consistent crushing performance and prevents damage to other components of the crusher. Additionally, monitor the product's particle size; if it starts to deviate from specifications, it may indicate that the liner is wearing out and needs replacement.

**Tips:** To prolong the life of your bowl liner, ensure that the material being fed into the crusher is appropriately sized for the machine. Overloading can expedite wear. Additionally, regular maintenance, such as lubrication and thorough inspections, can help you spot issues early, allowing for timely replacements and minimizing downtime.