-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of mining and construction, the significance of Cone Crusher Parts cannot be overstated. These components are vital for the efficient operation of cone crushers. According to industry expert John Smith, “Without the right Cone Crusher Parts, peak performance is impossible.” This statement highlights the integral role these parts play in crushing operations.

Cone Crusher Parts include various elements like liners, mantles, and bushings. Each part has a specific function that contributes to the overall performance. For instance, the mantle is crucial for crushing materials effectively. If these components wear out or fail, the entire system suffers. Understanding their importance is critical for maintenance and productivity.

Neglecting the quality of Cone Crusher Parts can lead to unforeseen challenges. Operators may experience downtime, inefficiencies, and costly repairs. Hence, investing in high-quality parts is necessary. Yet, many still overlook this aspect, thinking all parts are interchangeable. This oversight can cause serious operational issues. It’s essential to appreciate the value of each part to enhance performance and avoid setbacks.

Cone crushers are vital in the mining and aggregate industries. They crush materials into a desired size, making them essential for various operations. Understanding the parts of a cone crusher can greatly improve its performance and longevity.

The main parts include the mantle, bowl liner, and concave. The mantle is a moving piece that crushes the material against the bowl liner. It is crucial for the crushing process. The bowl liner surrounds the mantle and helps direct the flow of material. Another important part is the shaft, which transmits power from the motor to the mantle. Without these key components, a cone crusher cannot function efficiently.

Regular inspection of these parts is necessary. Wear and tear can occur over time. A damaged mantle or liner can significantly affect output. Operators must stay vigilant and replace parts when they show signs of excessive wear. Ignoring these maintenance steps can lead to larger issues, impacting productivity. Therefore, understanding cone crusher parts is not just useful; it is vital for success in mining operations.

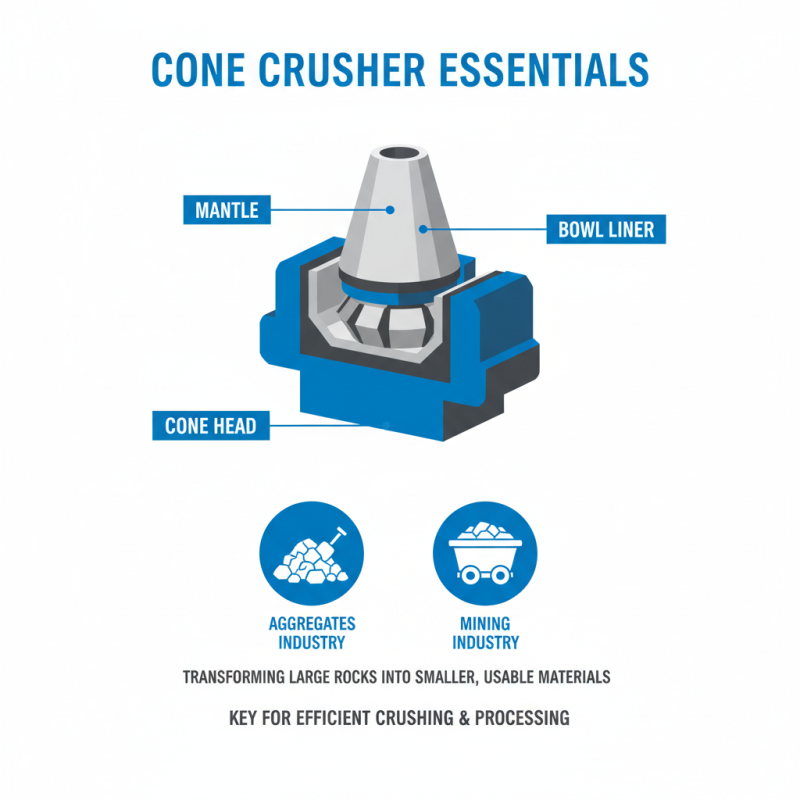

Cone crushers are vital in the aggregates and mining industries. They crush large rocks and stones into smaller pieces. Key components of a cone crusher include the mantle, bowl liner, and cone head. Understanding these parts is essential for efficient operation.

The mantle is a moving part that crushes material by squeezing it against the other fixed cone. It wears out over time and requires regular inspection. The bowl liner, which is fixed, also experiences significant wear. Data suggests that maintenance issues arise from neglecting these components. The life expectancy of a mantle and bowl liner is often around 800-1000 hours, which can vary based on material type.

**Tip:** Regular lubrication and inspection of wear parts can extend their lifespan. Checking for wear indicators can save time and money.

Another crucial part is the cone head. It supports the entire assembly and withstands heavy forces during operation. If damaged, it can lead to catastrophic failure. Properly aligned cone crushers can improve material throughput by up to 20%, according to industry studies. Maintaining these parts is key to long-term success.

**Tip:** Always use the correct torque specifications during installation. This ensures optimal performance and reduces the risk of failure.

Cone crushers play a vital role in the mining and aggregate industries. Their efficiency largely depends on the specific components that comprise the machine. Each part of a cone crusher has a unique function, contributing to the overall performance. For example, the mantle and concaves are crucial for crushing material. These components endure extreme wear and tear. Regular inspection and timely replacement are essential for uninterrupted operation.

The hydraulic system is another key component. It maintains fluid levels and controls pressure. If not properly maintained, it can lead to operational failures. A study from the International Journal of Minerals highlights that a well-functioning hydraulic system can increase productivity by up to 30%. This is significant, considering the high costs of downtime. Moreover, the crusher's frame provides structural support. A weakened frame may lead to misalignment and potential machinery failure.

Regular maintenance is often neglected. This oversight can reduce each part's lifespan and efficiency. For instance, a worn-out drive belt can impact performance and lead to increased energy costs. Reports indicate that effective maintenance practices can extend equipment life by 20-30%. Each part's role in a cone crusher is crucial. Understanding and addressing these factors can lead to improved performance in operations.

High-quality cone crusher parts are crucial for maximizing efficiency in crushing operations. Without these parts, performance can suffer significantly. The components must endure high impact and pressure. If they degrade quickly, production losses are inevitable. Investing in quality parts leads to reduced downtime and better output.

Tips: Regularly inspect parts for wear. Small issues can escalate quickly. Replace worn-out components before they fail. This proactive approach shields against costly repairs.

Choosing the right materials for cone crusher parts is essential. Cheap substitutes can save money initially but lead to frequent breakdowns. Think about the long-term impact on operations. Strong and durable parts enhance overall productivity. They provide a reliable operation that is often underestimated.

Tips: Consider compatibility when purchasing parts. Mismatched components might fit but can cause severe operational problems. Evaluate suppliers carefully to find reliable options.

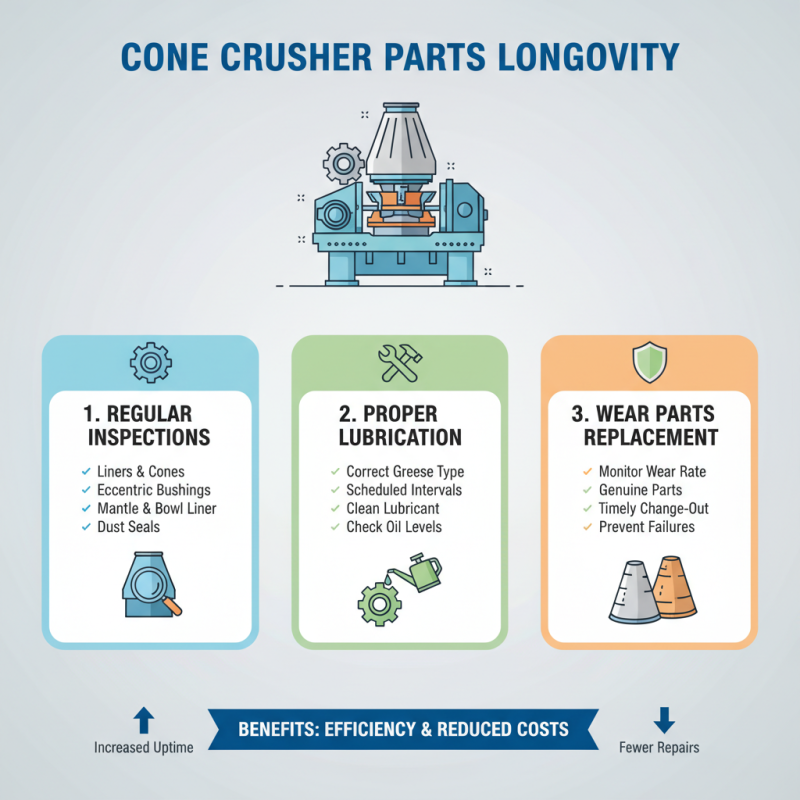

Maintaining cone crusher parts is crucial for their longevity. Proper care ensures efficient operation and reduces costly repairs. Regular inspections of wear parts like liners and cones can prevent unexpected failures. These parts endure significant stress, and overlooking them might lead to performance issues.

One important tip is to check the lubrication regularly. Insufficient lubrication can lead to overheating and damage. Clean the grease fittings often to avoid blockages. Another tip is to monitor the gap settings. A misaligned gap can cause premature wear. Adjust it according to the manufacturer's specifications.

Keeping an eye on vibration levels is also essential. Excessive vibrations may indicate wear or misalignment. This could lead to serious mechanical failures. Schedule routine maintenance and not just when problems arise. Regular care prolongs the life of cone crusher parts and enhances productivity. Ignoring these tasks can result in bigger headaches down the road.