-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The global market for Cone Crusher Parts is projected to experience substantial growth, with industry reports estimating a compound annual growth rate (CAGR) of approximately 5.5% from 2020 to 2025. This surge is driven by the increasing demand for mining and construction activities, particularly in emerging economies where infrastructural development is accelerating. As the need for efficient and durable cone crushers rises, choosing the right parts becomes critical for optimizing performance and ensuring longevity. With a variety of options available in the market, understanding the essential factors to consider when selecting Cone Crusher Parts is vital for achieving maximum productivity and cost-effectiveness. In this blog, we will unveil seven essential tips to guide you in making informed decisions tailored to your specific needs, thus positioning you to capitalize on the potential growth and advancements within the industry.

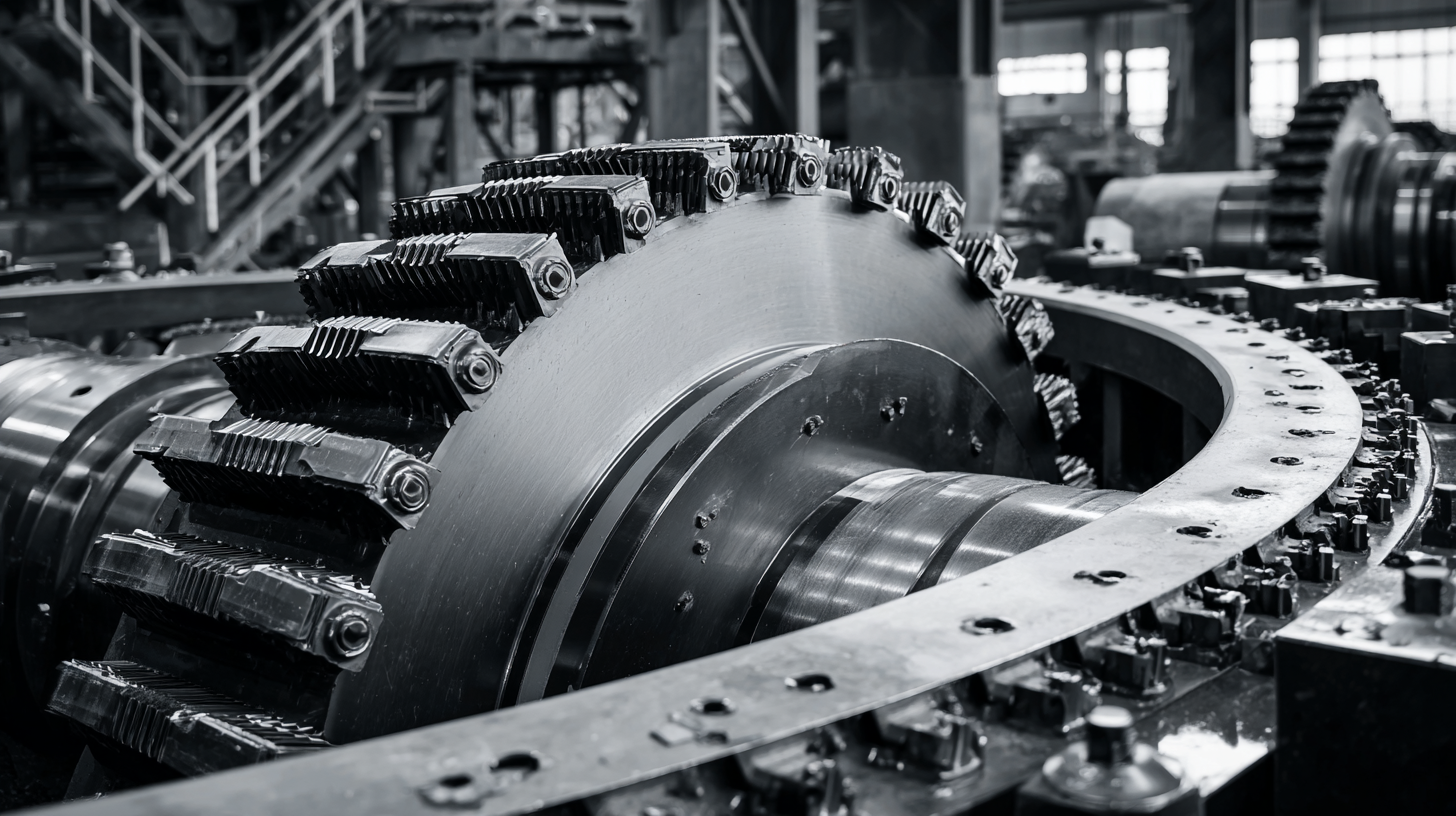

When it comes to selecting the right cone crusher parts, understanding the various types and their functions is crucial for optimizing operational efficiency. Cone crushers are equipped with numerous components, each serving a specific purpose in the crushing process. Key parts include liners, mantles, and bowls, all of which play vital roles in the crushing functionality. Recent advancements in materials such as specialized steels and alloys have significantly improved the wear resistance and longevity of these components, allowing for better performance under demanding conditions.

In the ever-evolving landscape of mining and material processing, the necessity for upgrading to modern components cannot be overstated. Upgraded series of cone crushers are now equipped with advanced automation and connectivity systems, enhancing operational capabilities. Consequently, operations can reduce downtime and maintain efficiency even when faced with challenging material types. Understanding these developments and the specific functions of each cone crusher part will empower operators to make informed decisions, ultimately improving their productivity and reliability in the field.

When selecting cone crusher parts, understanding industry production standards is crucial to ensure the longevity and efficiency of your machinery. According to a report from the Mining Equipment Manufacturers Association, parts manufactured to ISO 9001 standards have shown a 20% increase in durability compared to those produced under less stringent guidelines. This highlights the importance of sourcing components that meet high manufacturing standards, as they directly impact performance and maintenance costs.

Material quality is another critical factor in choosing the right cone crusher parts. The American Society for Testing and Materials (ASTM) provides rigorous specifications for materials used in crusher components. For instance, parts made from high tensile strength alloy steels exhibit improved wear resistance, which is vital for maintaining operational efficiency. A study published in the International Journal of Mining Science and Technology demonstrated that utilizing components made from premium materials can reduce downtime by 15%, underscoring the necessity of evaluating material quality in the selection process.

When selecting cone crusher parts, one critical factor that cannot be overlooked is the material composition. The durability and overall performance of these components are heavily influenced by the materials used in their construction. High-quality alloys, such as manganese steel, are often utilized due to their superior resistance to wear and tear. This resilience is vital in ensuring that the parts withstand the harsh operational conditions typically associated with crushing applications, thereby enhancing the lifespan of the equipment.

Moreover, the specific requirements of your crushing task can dictate the optimal material choice. For instance, if your operation involves crushing abrasive materials, opting for parts with higher toughness and wear resistance can significantly reduce downtime and maintenance costs. Conversely, in environments where impact resistance is needed, specialized materials that absorb shock can offer better performance. Ultimately, a thorough assessment of the material composition not only influences the durability of cone crusher parts but also impacts the efficiency and output of the crushing process.

When selecting cone crusher parts for your operations, understanding key performance metrics is crucial. A recent industry report from Grand View Research indicates that the global cone crusher market is expected to reach $4.5 billion by 2027, emphasizing the increasing demand for high-performance machinery. Key metrics include wear life, material composition, and structural integrity, as these factors significantly impact efficiency and operational costs.

Tip 1: Prioritize wear life when choosing parts. According to a study published in the Journal of Construction and Building Materials, components with higher wear resistance can extend the lifespan of the entire cone crusher, reducing downtime and maintenance costs.

Tip 2: Evaluate the material composition of the parts. Different alloys and heat treatment processes can enhance durability and performance. For example, parts made from manganese steel often provide better resistance to impact and wear, facilitating smoother operations.

Incorporating these considerations into your selection process will not only enhance the performance of your cone crusher but also ensure a more cost-effective operation in the long term.

When it comes to maintaining the performance of cone crushers, it's essential to not only choose the right parts but also to understand the common issues that can arise. One prevalent problem is the wear and tear of components, which can significantly impact the efficiency and lifespan of the machinery. According to industry reports, up to 30% of operational costs in mining and quarrying can be attributed to equipment downtime caused by worn-out parts. By proactively identifying these issues and opting for high-quality replacements, operators can mitigate the risks associated with decreased productivity.

Upgrading to the latest generation of components can also play a crucial role in overcoming these challenges. Recent advancements, such as the 5th Generation technology, have demonstrated enhanced reliability and efficiency. These upgrades not only minimize maintenance concerns but also improve throughput and reduce operational costs by approximately 15% over older models. Therefore, selecting the best cone crusher parts means considering both immediate needs and future upgrades, ensuring that your operations remain efficient and cost-effective.

| Tip | Common Problems | Effective Solutions |

|---|---|---|

| 1. Understand the Material | Poor wear resistance | Choose high-quality alloy materials |

| 2. Check Compatibility | Incompatibility issues | Verify specifications with equipment |

| 3. Evaluate the Supplier | Subpar quality parts | Research supplier reputation and reviews |

| 4. Consider Cost vs Quality | Overpriced low-quality parts | Balance cost with expected lifespan |

| 5. Inspect Part Design | Design flaws leading to breakage | Choose well-reviewed designs and innovations |

| 6. Maintenance Practices | Frequent wear and tear | Establish a regular maintenance schedule |

| 7. Seek Expert Advice | Lack of knowledge on effective choices | Consult industry experts before purchasing |