-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

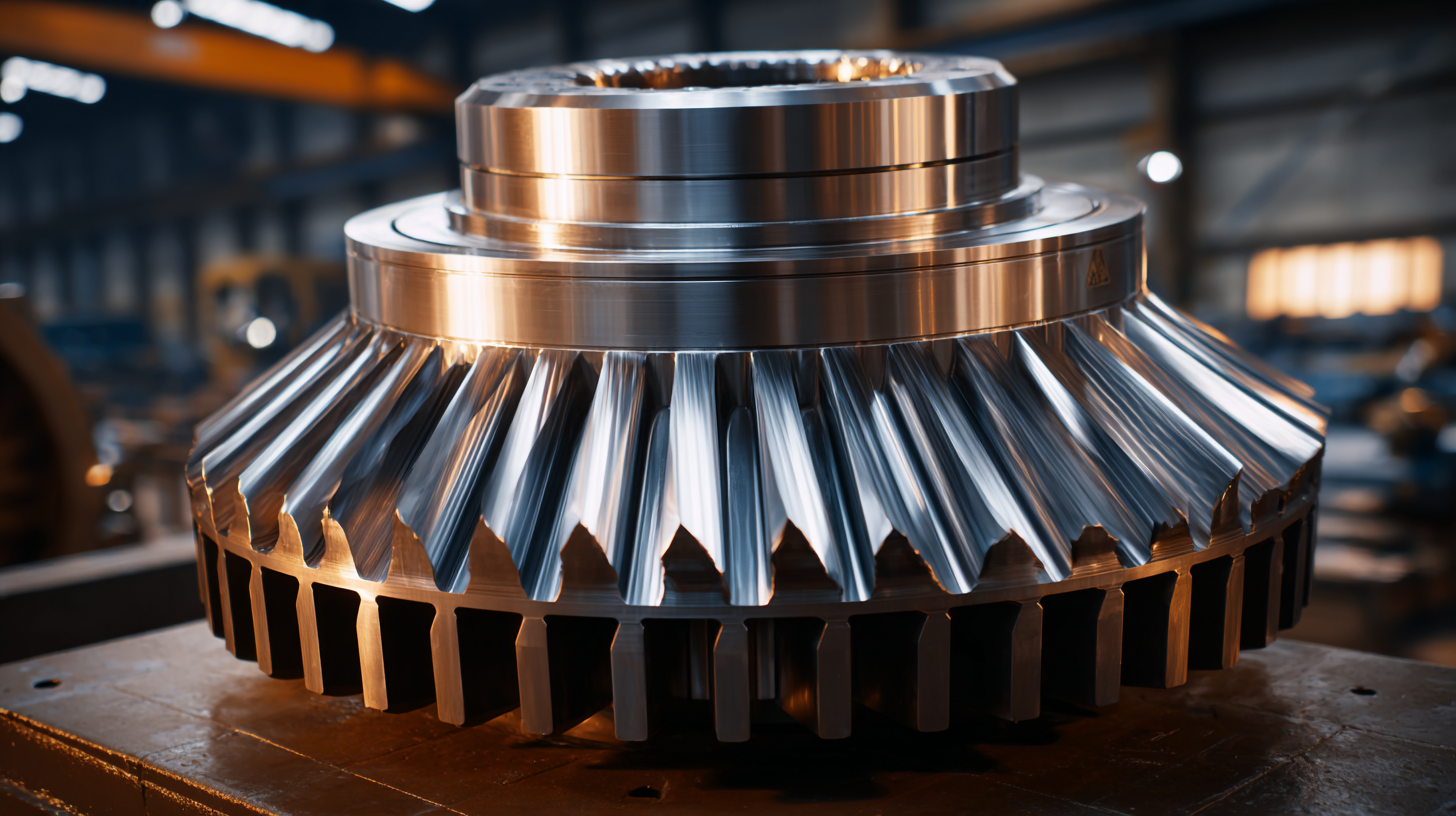

In the rapidly evolving landscape of mining and construction, the demand for efficient and durable machinery has never been more crucial. The global cone crusher market, valued at approximately $1.3 billion in 2020, is projected to reach $1.9 billion by 2025, highlighting a robust CAGR of 7.5%.

Central to this growth is the innovative technology surrounding the Cone Crusher Bowl, a key component that enhances crushing efficiency and product quality. As manufacturers strive for excellence, advancements in materials and design are set to revolutionize the performance and lifespan of these vital tools. With China's rich heritage in manufacturing, the commitment to quality and innovation promises to benefit global buyers seeking high-performance Cone Crusher Bowls tailored to meet the rigorous demands of modern operations.

As we look to 2025, understanding these future innovations will be indispensable for anyone looking to stay competitive in the industry.

Central to this growth is the innovative technology surrounding the Cone Crusher Bowl, a key component that enhances crushing efficiency and product quality. As manufacturers strive for excellence, advancements in materials and design are set to revolutionize the performance and lifespan of these vital tools. With China's rich heritage in manufacturing, the commitment to quality and innovation promises to benefit global buyers seeking high-performance Cone Crusher Bowls tailored to meet the rigorous demands of modern operations.

As we look to 2025, understanding these future innovations will be indispensable for anyone looking to stay competitive in the industry.

In the ever-evolving landscape of mining and aggregate industries, advancements in material science are set to transform cone crusher bowl technology by 2025. The adoption of innovative materials will enhance durability, reduce wear, and improve overall performance. Today’s manufacturers are focusing on high-strength alloys and composites that resist deformation under extreme pressures, ensuring longer service life and reduced maintenance costs.

In the ever-evolving landscape of mining and aggregate industries, advancements in material science are set to transform cone crusher bowl technology by 2025. The adoption of innovative materials will enhance durability, reduce wear, and improve overall performance. Today’s manufacturers are focusing on high-strength alloys and composites that resist deformation under extreme pressures, ensuring longer service life and reduced maintenance costs.

To maximize the benefits of these advancements, buyers should consider a few essential tips. Firstly, always evaluate the material specifications provided by manufacturers. Products made from advanced alloys or updated composites can significantly outperform traditional materials. Secondly, stay informed about testing standards and certifications that prove a material's reliability in various operational conditions. Lastly, explore options for customization, as tailored solutions can better fit specific application needs and enhance productivity.

As we move closer to 2025, the innovations in cone crusher bowl technology will not only redefine product functionality but also contribute to more sustainable industry practices. By leveraging advancements in material science, global buyers can ensure they invest in state-of-the-art equipment that meets their operational demands while reducing environmental footprints.

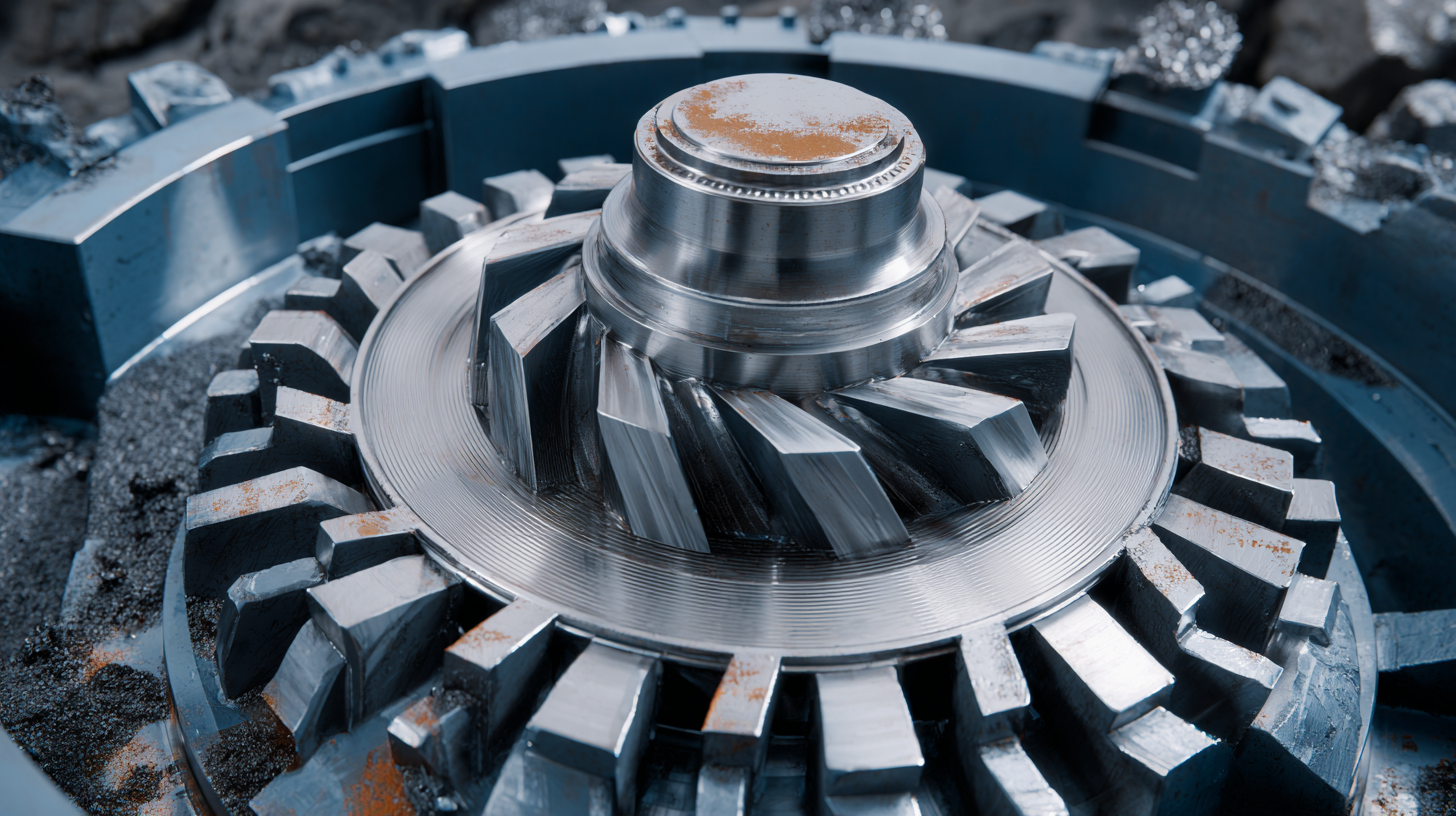

As we look ahead to 2025, the integration of smart technology in cone crusher bowl design is poised to revolutionize the mining and aggregate industries. Advanced data analytics, machine learning, and IoT connectivity are enabling more efficient operation and maintenance of these vital machines. By leveraging real-time data feeds, operators can monitor wear patterns and predict potential failures, allowing for proactive maintenance and minimal downtime. This not only enhances performance but also significantly reduces operational costs.

Moreover, innovations in automation are set to redefine user experiences and operational efficiency. Automated adjustments to the cone settings can optimize the throughput and product quality in response to changing material conditions. Such adaptability ensures that the crushers function at their peak performance levels. The inclusion of smart sensors will also facilitate remote monitoring and control, providing operators with unprecedented oversight of their equipment. As a result, the future of cone crusher bowl technology promises not only cost savings but also a leap towards a more sustainable and efficient industry.

This chart illustrates the projected performance improvements in cone crushers with the integration of smart technology by the year 2025. The data represents different performance metrics including efficiency, energy consumption, and maintenance needs.

As the global demand for sustainable manufacturing practices increases, the cone crusher bowl technology is poised for significant innovations by 2025. According to a recent report by Grand View Research, the global crushers market is projected to reach USD 4.98 billion by 2025, with a rising emphasis on eco-friendly materials and processes. This trend highlights the industry's shift towards more sustainable practices, including the adoption of recyclable alloys and energy-efficient production methods that minimize carbon footprints.

For manufacturers aiming to enhance sustainability in their cone crusher bowls, employing advanced materials is crucial. Researchers note that using high-strength, lightweight composites can reduce overall resource consumption while maintaining structural integrity. Furthermore, integrating renewable energy sources into the manufacturing process can significantly decrease operational emissions.

**Tips:**

1. Consider sourcing materials from local suppliers to reduce transportation emissions and support local economies.

2. Explore technologies such as 3D printing, which can optimize material use and energy efficiency in production.

3. Regularly audit the manufacturing processes for waste reduction opportunities and implement recycling programs to promote a circular economy.

As manufacturers look towards the future of cone crusher bowl technology, customization is becoming a key consideration for global markets. Different regions have unique operational challenges and material characteristics, prompting a demand for tailored solutions. By offering customizable options, manufacturers can ensure that their products not only meet specific local requirements but also enhance efficiency and productivity. This approach will allow companies to innovate while aligning their technologies with diverse market demands.

In 2025, we anticipate that advanced customization will extend beyond simple size adjustments. Innovations such as modular designs and interchangeable components will enable users to modify their cone crushers according to fluctuating operational needs. This flexibility will be particularly beneficial for businesses operating in dynamic environments, where material properties and processing requirements can change rapidly. By prioritizing customization, manufacturers will empower their customers to achieve optimal performance, thereby creating a competitive edge in the global market.

| Customization Option | Market Demand (%) | Innovative Feature | Expected Benefit | Launch Year |

|---|---|---|---|---|

| Adaptive Bowl Optimization | 35% | Real-time adjustment of bowl settings | Enhanced efficiency and reduced wear | 2025 |

| Material Composition Customization | 30% | Options for high wear resistance alloys | Longer service life and lower maintenance | 2025 |

| Integration with IoT Sensors | 25% | Smart diagnostics and predictive maintenance | Reduced downtime and improved safety | 2025 |

| Reversible Bowl Design | 10% | Bowl can be flipped for extended use | Increased lifespan and cost-effectiveness | 2025 |

| Eco-friendly Materials | 20% | Sustainably sourced components | Reduced environmental impact | 2025 |

As we look towards 2025, the trends in crusher bowl technology are expected to undergo significant advancements driven by the need for efficiency and sustainability in mining and aggregate industries. Future design innovations will likely focus on enhanced material durability and weight optimization, aimed at improving the longevity and performance of crusher bowls. Manufacturers may implement advanced materials such as high-strength composites or hybrid alloys, which can withstand higher operational stresses while reducing wear and tear.

Alongside material innovations, the integration of smart technology will become prevalent. Predictive maintenance systems utilizing IoT (Internet of Things) can monitor the performance of crusher bowls in real-time, allowing for timely interventions and reduced downtime. Moreover, automation in design processes will enable customization based on specific mining conditions or customer requirements, making the next generation of crusher bowls not only more efficient but also tailored to varied operational demands. As we embrace these changes, the global buyers of 2025 will be equipped with tools that enhance productivity and sustainability, ensuring that their operations are both competitive and environmentally responsible.