-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of construction, efficiency is paramount. "Construction Machinery Wear Parts" play a crucial role in maintaining equipment performance. When parts wear out, machinery can fail, leading to costly delays. Knowing the top brands of wear parts is essential for any contractor.

Quality parts can dramatically influence productivity. Some brands have built a reputation over the years. They are known for durability and reliability. However, not all brands are equal. Some might struggle with consistency and lead to unexpected breakdowns. It's vital to research before purchasing.

Investing in the right wear parts is an opportunity, not just an expense. Poor choices can result in setbacks that impact timelines. Brands that excel often prioritize innovation and customer satisfaction. Learning about these brands ensures you make informed decisions in the field.

Construction machinery wear parts are essential components that ensure the longevity and efficiency of heavy equipment. According to industry reports, about 70% of machinery downtime is attributed to wear and tear on these parts. This highlights their critical role in maintaining operational productivity.

These parts, including blades, teeth, and tracks, can dramatically affect performance. For example, worn-out teeth on excavators can reduce digging efficiency by up to 30%. Regular maintenance and timely replacements can prevent costly delays. The average lifespan of these wear parts varies, but many only last around 1,000 operating hours under heavy use. Neglecting them can lead to unexpected breakdowns.

It's noteworthy that the quality of wear parts greatly influences machinery performance. Low-quality components might offer short-term savings but can increase long-term costs due to frequent replacements. Investing in durable wear parts is crucial. However, the market is saturated with options, making it challenging for operators to make informed choices. The need for awareness and research is paramount in selecting the right products.

| Part Type | Material | Durability (Hours) | Cost ($) | Compatibility |

|---|---|---|---|---|

| Excavator Bucket Teeth | High Carbon Steel | 1000 | 50 | CAT, JCB, Komatsu |

| Bulldozer Cutting Edges | Alloy Steel | 800 | 75 | Komatsu, Hitachi |

| Loader Bucket Liners | AR400 Steel | 1200 | 90 | Caterpillar, Deere |

| Grader Blades | Chrome Moly Steel | 700 | 65 | Case, Volvo |

| Crusher Jaws | Manganese Steel | 1500 | 150 | Powerscreen, Terex |

The construction machinery wear parts market is shaped by key players driving innovation. Research estimates the global market for these parts is valued at over $50 billion. This figure highlights the significance of durability and efficiency in machinery operations. Key manufacturers focus on quality and performance, but not all succeed equally.

Some players have made strides in material technology. They utilize advanced alloys to prolong life and reduce wear. Despite progress, some companies still struggle with supply chain issues. This inconsistency can lead to delays and dissatisfied customers. The competition is fierce, pushing firms to enhance their product offerings continually.

Market reports indicate a strong demand for replacement parts driven by aging machinery. This creates opportunities for both established names and new entrants. However, the focus on sustainability is pushing companies to reconsider materials. Many are exploring eco-friendly options, yet not all have fully embraced this shift. The balance between performance and environmental impact remains a complex challenge.

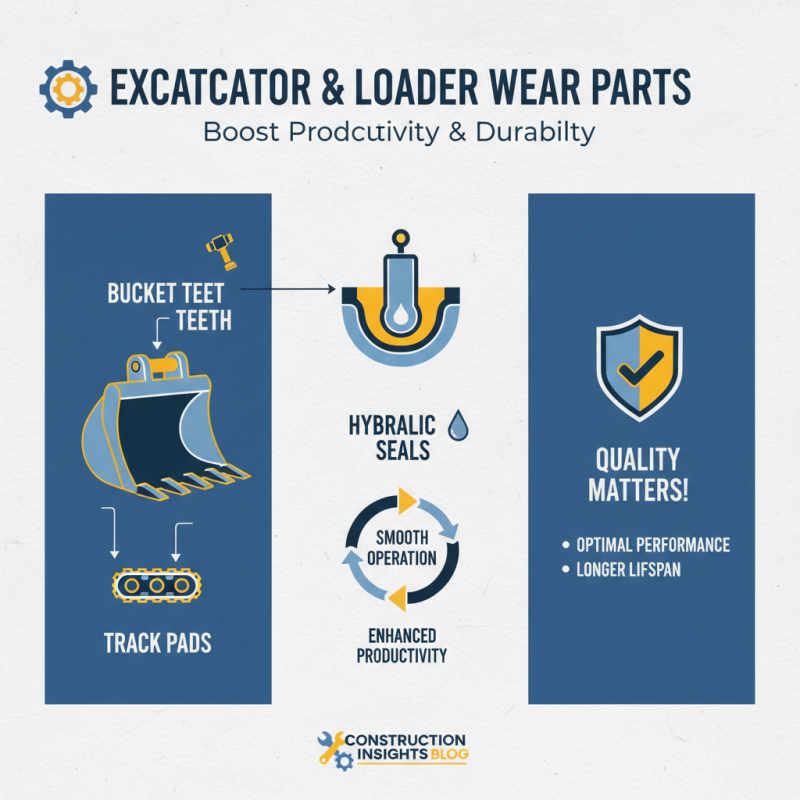

When it comes to excavators and loaders, the importance of wear parts cannot be understated. These components play a vital role in ensuring smooth operation and enhanced productivity. Regular wear parts include bucket teeth, track pads, and hydraulic seals. Choosing the right quality is crucial for performance and durability.

For excavators, reliable wear parts improve digging efficiency and reduce downtime. Having the right bucket teeth can make a significant difference in material handling. However, not all wear parts are created equal. Some may wear down quickly under harsh conditions. This inconsistency can affect operations and increase costs over time.

Loaders also rely heavily on their wear components for optimal performance. The choice of wear parts affects loading accuracy and overall machine life. High-quality loader wear parts can minimize wear and tear. Yet, many operators overlook the value of investing in reliable parts, often opting for cheaper options. This short-term thinking sometimes leads to greater long-term expenses.

Innovative technologies have transformed the manufacturing of wear parts in the construction machinery sector. Advanced materials are now being used to enhance durability. These materials provide longer service life, reducing downtime and maintenance costs. For instance, composites and high-strength alloys are gaining popularity. They withstand extreme conditions better than traditional options.

3D printing is another game changer. This technology allows for rapid prototyping and customization. Manufacturers can create wear parts on demand, reducing lead times significantly. However, this approach is still evolving. Not every design translates well into 3D. Some challenges remain in ensuring consistent quality and performance.

Automation in production processes is also noteworthy. Robotics streamline manufacturing, boosting efficiency. Yet, dependence on machines introduces its own issues. For instance, program errors can lead to defects in parts, requiring thorough checks. Manufacturers must adapt to these technologies carefully, ensuring they blend seamlessly with traditional practices. Embracing innovation is vital, but reflection on these changes is equally important.

When selecting wear parts for construction machinery, several factors come into play. Quality should be a top priority. You want parts that can withstand heavy use and harsh conditions. Look for items that show strong durability. This can mean the difference between a short lifespan and long-lasting performance.

Another essential factor is compatibility. The wear parts must fit your machinery perfectly. Misfitting parts can lead to inefficiencies and damages. It’s wise to check the specifications of both the parts and the machinery. Furthermore, consider the manufacturer’s reputation. An established brand often indicates reliability, but this isn’t the only measure of quality.

Pricing cannot be overlooked. Affordable options are tempting, yet cheaper parts might lack the necessary durability. Look for a balance between cost and quality. Compare different options. Sometimes, investing a little more pays off in the long run. Test and review can guide your decision-making.