-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Understanding Gyratory Crusher Parts is crucial for those in the mining and construction industry. John Smith, a seasoned expert in crushing technology, emphasizes, "Choosing the right Gyratory Crusher Parts can influence efficiency significantly." Manufacturers must pay close attention to the components that make up these machines.

The Gyratory Crusher operates under extreme conditions, making its parts susceptible to wear and tear. From the mantle to the spider cap, each part plays a significant role in performance. A single malfunction can lead to costly downtimes. It’s essential to recognize that not all parts are created equal. Quality should not be compromised for cost.

While many organizations overlook the importance of regular maintenance of Gyratory Crusher Parts, this can have serious consequences. Over time, even small issues can escalate into major problems. Understanding these parts helps in making informed decisions, but too often details are ignored. Ignorance can lead to operational inefficiencies and increased costs. The challenge remains ensuring all components receive the attention they deserve.

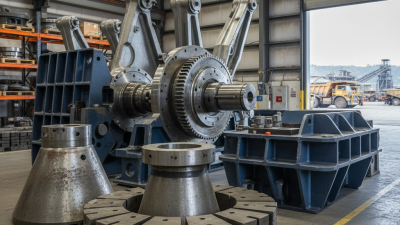

Gyratory crushers play a crucial role in the mining and aggregate industries. These machines crush large rocks into smaller pieces, facilitating the extraction of minerals. Their design features a conical shape with a wide opening at the top for input material. This allows for efficient processing of bulk materials.

In many industrial setups, the importance of gyratory crushers cannot be overstated. They provide high throughput rates compared to other types of crushers. The crushing mechanism is also relatively simple and effective. However, they require regular maintenance. Components like the mantle and concave wear over time. Users often overlook these parts, leading to decreased efficiency.

The size and scale of gyratory crushers can sometimes lead to operational challenges. For instance, handling large, hard materials can cause unexpected breakdowns. Operators need to be aware of these risks. They should monitor wear parts closely. Proper training and maintenance are crucial for optimal performance. Understanding these factors can result in significant improvements in productivity.

Gyratory crushers are vital for heavy industry. Their key components play specific roles in operation. Understanding these parts helps in maintenance and performance.

The mantle is crucial. It crushes material against the bowl liner. Both pieces wear over time. Regular inspection is essential to ensure efficiency. Other vital parts include the spider and the eccentric assembly. The spider supports the main shaft. It absorbs vibrations during crushing. This role is often overlooked, yet it’s critical for stability.

The hydraulic piston assembly often faces problems. Its function is to adjust the gap between the mantle and bowl liner. If it fails, the machine can jam. Many operators miss checking hydraulic levels regularly. The main shaft is another key component. It transfers force, but excessive wear can lead to significant downtimes. Each part of the gyratory crusher interacts closely, and attention to detail can prevent costly repairs.

Gyratory crushers play a pivotal role in mining and aggregate production. Understanding the pivotal components is essential. The frame supports all other parts. It's robust, designed to withstand heavy loads. Reports suggest that a well-maintained frame can extend the life of a crusher by up to 30%.

Another crucial part is the mantle. It undergoes immense wear and tear. Studies indicate that changing the mantle at the right intervals can boost efficiency by over 15%. Additionally, the concave liner is vital for proper crushing. Its design affects the material's flow and can impact the overall productivity. The improvement in productivity linked to concave shape adjustments is significant.

It's also important to consider the spider and its role in maintaining the machine’s stability. A faulty spider can lead to serious operational issues. Moreover, the eccentric assembly generates the crushing action. This component must be regularly inspected for wear. Neglecting these parts can lead to costly downtime. While most operators focus on obvious parts, neglecting minor components leads to inefficiencies.

Regular inspections should not be overlooked.

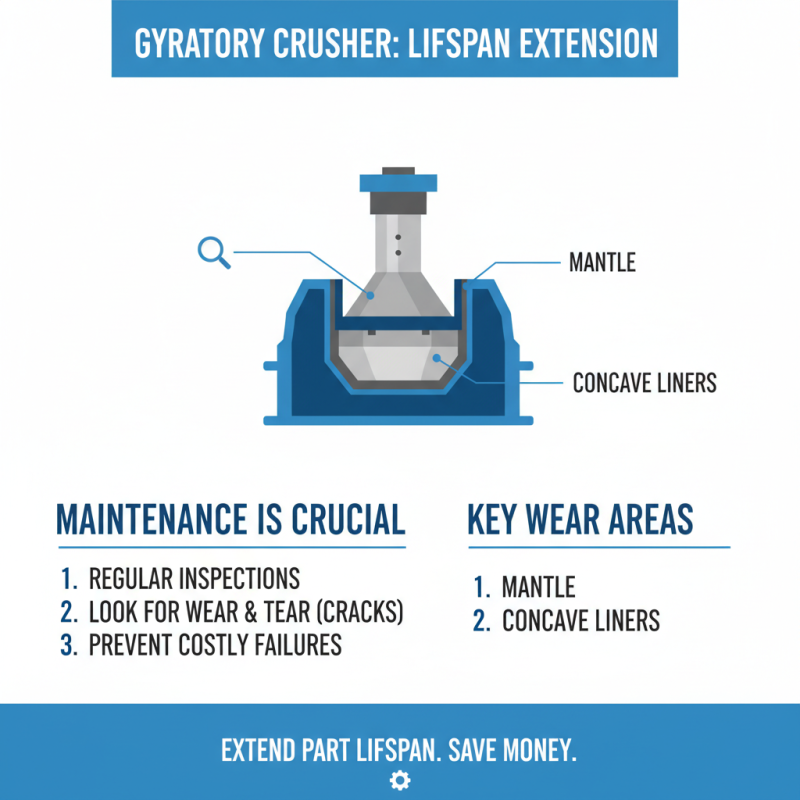

Maintaining gyratory crusher parts is crucial for extending their lifespan. Regular inspections can catch issues early. Look for signs of wear and tear. This can prevent bigger problems in the future. Typical wear areas include the mantle and concave liners. Inspect these components regularly for cracks and excessive wear.

Lubrication is another key factor. Proper lubrication reduces friction and heat, which can lead to failures. Ensure that the lubrication system is functioning well. Regularly check the oil levels and replace the oil as needed. Dirty oil can be harmful. In addition, keep the cooling system clean. A build-up of debris can lead to overheating and costly downtimes.

Sometimes, even with best practices, problems still arise. There may be unexpected breakdowns. It's essential to have a contingency plan in place. Training your team to handle issues efficiently can save time and money. This can improve maintenance routines. Constantly reevaluating your maintenance strategies can lead to better efficiency, although it may take time to find the right balance.

Gyratory crushers are vital in the mining and construction industries. However, common issues can hinder their performance. One prevalent problem is wear and tear on crucial parts like the mantle and concave liners. For instance, the U.S. Geological Survey reports that inadequate maintenance can lead to a 30% drop in output efficiency. Regular inspection is vital to avoid this decline.

Another significant challenge is hydraulic pressure loss. This can result from worn seals or hydraulic lines. Research indicates that even a minor leak can cause up to 20% decreased efficiency in operation. Monitoring hydraulic systems is critical for optimal function. Addressing these leaks promptly can save companies time and resources. Additionally, operators should recognize that unexpected vibrations often indicate underlying issues. These vibrations can lead to costly downtimes if ignored, making prompt analysis essential.

| Part Name | Common Issues | Troubleshooting Solutions |

|---|---|---|

| Mantle | Excessive wear, breakage | Regular inspection and replacement |

| Concave | Cracking, uneven wear | Align and replace if necessary |

| Spider Assembly | Loose or broken components | Tighten bolts or replace parts |

| Main Shaft | Bending, wear | Inspect regularly, replace if bent |

| Drive Motor | Overheating | Check cooling system, load management |

| Hydraulic System | Fluid leaks | Check seals, replace hoses |

| Discharge Chute | Blockages | Regular cleaning and inspection |

| Bearing | Excess noise or heat | Lubricate properly, check alignment |

| Dust Seal | Wear and tear | Inspect regularly, replace as needed |